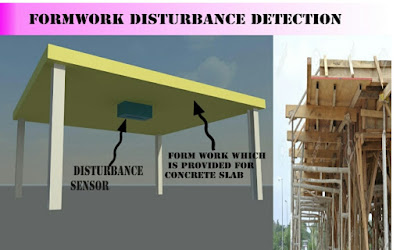

Formwork disturbance detection

Abstract—

This research deals with one of the common problems occur during the construction / life time of the structure i.e. failures of form work during the construction work of the structure due to the failure of the material ,external loads or by human error the placement of the formwork may displaced this may leads to structural failure of the building. Due this designed characteristics are May not achieved by the structure. Sometimes due to this reason building is demolished and reconstructed otherwise we have to go for external support by using steel supports at the end cost of construction is increases. In other hand, once structure constructed the settlement of the structure during life time of the building due to consolidation / structural failures. It may leads to failure the building and also danger for the usage. These types of settlements are detected by settlement detecting device in initial stage itself so, that accidents due to collapse of the building is avoided.

Not only these feature but it also inform every information as come from device to a site engineer or office by message to mobile through GSM module example: during concrete process if formwork settles . The message will be delivered to site engineer / office by alerting them by saying that “formwork disturbed please visit your site as early as possible”. In the same way all the messages will be sent to the office/ a site engineer.

This research deals with one of the common problems occur during the construction / life time of the structure i.e. failures of form work during the construction work of the structure due to the failure of the material ,external loads or by human error the placement of the formwork may displaced this may leads to structural failure of the building. Due this designed characteristics are May not achieved by the structure. Sometimes due to this reason building is demolished and reconstructed otherwise we have to go for external support by using steel supports at the end cost of construction is increases. In other hand, once structure constructed the settlement of the structure during life time of the building due to consolidation / structural failures. It may leads to failure the building and also danger for the usage. These types of settlements are detected by settlement detecting device in initial stage itself so, that accidents due to collapse of the building is avoided.

Not only these feature but it also inform every information as come from device to a site engineer or office by message to mobile through GSM module example: during concrete process if formwork settles . The message will be delivered to site engineer / office by alerting them by saying that “formwork disturbed please visit your site as early as possible”. In the same way all the messages will be sent to the office/ a site engineer.

Keyword: formwork, internet of things, consolidation, settlement

Introduction

When people heard civil engineering their imagination goes to hot sun, dust, risk, overnight duties, hard work, tiresome etc, because of the difficulties in civil Engineeringcompare to other fields. So, in this research work to simplify the civil field the settlement detecting part is get modern touch by using smart technologies. Sometimes due to this reason structure is demolished and reconstructed. Otherwise we have to go for external support by using steel supports at theend cost of construction is increases. In other hand, once structure constructed the settlement of the structure during life time of the building due to consolidation / structural failures. It may leads to failure of the building and also danger for the usage. Here bridge/underground construction work is taken as predominate then other because it’s short term process and also the settlement issues are more. The simple reason that settlement of bridge decks is a problem is that this differential settlement creates a bump in the roadway, which is a serious problem from the user point of view. As of 1995, there were 600,000bridges across the United States. Of these, 150,000 had problems with bumpsat bridge ends, resulting in estimated expenditures of $100 million per year toremedy the problem. (Briaud et. al., 1997) Using these totals, the nationalaverage would calculate to nearly $700 per year per bridge.The primary reason that “the bump at the end of the bridge” has been a problem

On highways for such a long time is that there are so many factors that cancontribute to settlement. There are, however, several commonly acceptedfactors that cause approach settlement to occur, and can be attributed as

THE FACTOR THAT LEADS TO THE FORMATION OF BUMPS:

I. Compression or Movement of Embankment Fill: Virtually all bridgeapproaches must be constructed on a fill embankment to allow the roadwayto meet the elevation of the bridge. If a fill material is selected that is

Compressible over time or inadequate compaction is conducted, the trafficloads may cause the approach fill to compress and often lead to settlement(lowering the roadway elevation), while the bridge elevation remains

constant. Typically, the settlement and/or compression of fill will approacha finite value and diminish over time. Also, embankment material must beresistant to slope failures and lateral displacements that would again lowerthe elevation of the roadway.

II. Settlement or Movement of Foundation Soil beneath theEmbankment: Obviously, if settlement or displacement is present and notcompletely occurring in the embankment fill, the soil foundation for theembankment is experiencing settlement. The foundation settlement ormovement is a result of both the dynamic traffic loads applied at theembankment surface and the static load of the embankment itself. As aresult, lightweight fill materials may hold promise for reducing settlement byminimizing the load applied to the foundation soil.With both cause I & II, the material used will likely be the native soilavailable in the area surrounding the bridge. The tremendous variability in

engineering properties of soils makes addressing these problems a difficulttask. Therefore, widely applicable solutions to bridge approach problemswill go beyond only soil concerns.

III. Design/ Construction Problems:

Often times, excessive settlement canoccur simply because design and/or construction issues are not properlyaddressed such as the type of bridge abutment to be used, joint selection,the method of compaction, or simply that the approach is not constructedaccording to design. One particular issue common in this area is that thebridge and bridge abutment are often constructed before final compactionof the approach, making it difficult to get compaction equipment in placenear the bridge end.

IV. Poor Drainage:

Poorly designed drainage systems can result in several

problems, which can lead to settlement. First, if fill and foundation materialreach a moisture content which is too high, the bearing capacity of the soilcan be lowered allowing settlement or movement of support soil and

lowering the elevation of the approach. Also, depending on the gradationof the fill and foundation soils, erosion can result beneath the approachroadway, also lowering the elevation of the approach.

FAILURE OF THE FORMWORK:

Formwork failure can result in concrete blowouts, falling formwork components or structural collapse, and has the potential to cause death or serious injury Formwork failures are often caused by: ... overloading of the formwork during concrete pouring operations

The main causes of formwork failure are:

- Improper stripping and shore removal

- Inadequate bracing

- Vibration

- Unstable soil under mudsills*, shoring not plumb

- Inadequate control of concrete placement

- Lack of attention to formwork details.

When people heard civil engineering their imagination goes to hot sun, dust, risk, overnight duties, hard work, tiresome etc, because of the difficulties in civil Engineeringcompare to other fields. So, in this research work to simplify the civil field the settlement detecting part is get modern touch by using smart technologies. Sometimes due to this reason structure is demolished and reconstructed. Otherwise we have to go for external support by using steel supports at theend cost of construction is increases. In other hand, once structure constructed the settlement of the structure during life time of the building due to consolidation / structural failures. It may leads to failure of the building and also danger for the usage. Here bridge/underground construction work is taken as predominate then other because it’s short term process and also the settlement issues are more. The simple reason that settlement of bridge decks is a problem is that this differential settlement creates a bump in the roadway, which is a serious problem from the user point of view. As of 1995, there were 600,000bridges across the United States. Of these, 150,000 had problems with bumpsat bridge ends, resulting in estimated expenditures of $100 million per year toremedy the problem. (Briaud et. al., 1997) Using these totals, the nationalaverage would calculate to nearly $700 per year per bridge.The primary reason that “the bump at the end of the bridge” has been a problem

On highways for such a long time is that there are so many factors that cancontribute to settlement. There are, however, several commonly acceptedfactors that cause approach settlement to occur, and can be attributed as

THE FACTOR THAT LEADS TO THE FORMATION OF BUMPS:

I. Compression or Movement of Embankment Fill: Virtually all bridgeapproaches must be constructed on a fill embankment to allow the roadwayto meet the elevation of the bridge. If a fill material is selected that is

Compressible over time or inadequate compaction is conducted, the trafficloads may cause the approach fill to compress and often lead to settlement(lowering the roadway elevation), while the bridge elevation remains

constant. Typically, the settlement and/or compression of fill will approacha finite value and diminish over time. Also, embankment material must beresistant to slope failures and lateral displacements that would again lowerthe elevation of the roadway.

II. Settlement or Movement of Foundation Soil beneath theEmbankment: Obviously, if settlement or displacement is present and notcompletely occurring in the embankment fill, the soil foundation for theembankment is experiencing settlement. The foundation settlement ormovement is a result of both the dynamic traffic loads applied at theembankment surface and the static load of the embankment itself. As aresult, lightweight fill materials may hold promise for reducing settlement byminimizing the load applied to the foundation soil.With both cause I & II, the material used will likely be the native soilavailable in the area surrounding the bridge. The tremendous variability in

engineering properties of soils makes addressing these problems a difficulttask. Therefore, widely applicable solutions to bridge approach problemswill go beyond only soil concerns.

III. Design/ Construction Problems:

Often times, excessive settlement canoccur simply because design and/or construction issues are not properlyaddressed such as the type of bridge abutment to be used, joint selection,the method of compaction, or simply that the approach is not constructedaccording to design. One particular issue common in this area is that thebridge and bridge abutment are often constructed before final compactionof the approach, making it difficult to get compaction equipment in placenear the bridge end.

IV. Poor Drainage:

Poorly designed drainage systems can result in several

problems, which can lead to settlement. First, if fill and foundation materialreach a moisture content which is too high, the bearing capacity of the soilcan be lowered allowing settlement or movement of support soil and

lowering the elevation of the approach. Also, depending on the gradationof the fill and foundation soils, erosion can result beneath the approachroadway, also lowering the elevation of the approach.

FAILURE OF THE FORMWORK:

Formwork failure can result in concrete blowouts, falling formwork components or structural collapse, and has the potential to cause death or serious injury Formwork failures are often caused by: ... overloading of the formwork during concrete pouring operations

The main causes of formwork failure are:

- Improper stripping and shore removal

- Inadequate bracing

- Vibration

- Unstable soil under mudsills*, shoring not plumb

- Inadequate control of concrete placement

- Lack of attention to formwork details.

If these types of settlements happened in real case that time bridge /underground construction structure will be in danger zone. If these types of settlements in initial stage itself so, that accidents due to collapse of the bridge / structure is avoided. To find these types of settlement is possible in this advanced device.

INTELIGENT SETTLEMENT DETECTING DEVICE is advanced device which detect the settlement occurred in a structure during construction / after few years of construction.

DETERMINATION OF FAILURE OF THE FORMWORK AND SETTLEMENT OF THE STRUCTURE AFTER CONSTRUCTION:

INTELIGENT SETTLEMENT DETECTING DEVICE

It is a smart device which will detect the settlement or disturbance.

This device consists of sensor and these sensors are helps in detecting settlement.

The detected the settlement is immediately informed to a owner or to site engineer.

Also the amount of settlement values is sent along with the alert message to a cell phone.

INTELIGENT SETTLEMENT DETECTING DEVICE is advanced device which detect the settlement occurred in a structure during construction / after few years of construction.

DETERMINATION OF FAILURE OF THE FORMWORK AND SETTLEMENT OF THE STRUCTURE AFTER CONSTRUCTION:

INTELIGENT SETTLEMENT DETECTING DEVICE

It is a smart device which will detect the settlement or disturbance.

This device consists of sensor and these sensors are helps in detecting settlement.

The detected the settlement is immediately informed to a owner or to site engineer.

Also the amount of settlement values is sent along with the alert message to a cell phone.

HOW IT’S WORKS:

The formwork is fixed with ISDD and the disturbances are detected by the ultrasonic sensorUltrasonic sensors are based on measuring the properties of sound waves with frequency above the human audible range.

The formwork is fixed with ISDD and the disturbances are detected by the ultrasonic sensorUltrasonic sensors are based on measuring the properties of sound waves with frequency above the human audible range.

They are based on three physical principles: time of flight, the Doppler Effect, and the attenuation of sound waves. Ultrasonic sensors are non-intrusive in that they do not require physical contact with their target, and can detect certain clear or shiny targets otherwise obscured to some vision-based sensors. On the other hand, their measurements are very sensitive to temperature and to the angle of the target. The sensors will continuously measure the distance between bottom surfaces of the bridge to ground.

These values are sends to the microcontroller then the values are compiled by the microcontroller as per the coding if feed into the controller. Usually 1-2 cm of settlement is allowed in the structure. If allowable limit is say 2cm then when settlement is occurred more than 2cm then the alert messages are sends to the owner or the site engineer. So that that person will came to know that settlement is happened than immediately person can think about safety measurements.

Using it as a permanent settlement detector in the building:

Same device will be fitted to the buildings to find the settlement or to avoid accidents due to collapse.

Using it as a permanent settlement detector in the building:

Same device will be fitted to the buildings to find the settlement or to avoid accidents due to collapse.

ADVANTAGES:

This device is easy to fix and portable one.

No requirement human for the monitoring.

Device is automated one and the embedded with internet of things. So that all messages are send to a owner / site engg.

The device is can be used for many buildings.

Starting of new enterprises.

Quality of constructions increases

Economical

Safety for building users

CONCLUSIONS:

Formwork / settlement measurement is very essential for the important buildings, structural buildings to avoid the failures due to formwork displacement / failures of the supports. It may leads to structural failure and human life may under danger. Till today there are no inventions for formwork disturbance measurement.

This device is easy to fix and portable one.

No requirement human for the monitoring.

Device is automated one and the embedded with internet of things. So that all messages are send to a owner / site engg.

The device is can be used for many buildings.

Starting of new enterprises.

Quality of constructions increases

Economical

Safety for building users

CONCLUSIONS:

Formwork / settlement measurement is very essential for the important buildings, structural buildings to avoid the failures due to formwork displacement / failures of the supports. It may leads to structural failure and human life may under danger. Till today there are no inventions for formwork disturbance measurement.

Comments

Post a Comment